In HVAC systems, the performance of aluminum fin stock, a core component of heat exchange, directly determines the system’s energy efficiency and operational stability. Haomei aluminum fin stock for HVAC systems cover two main series: 3003 and 8011, with thicknesses ranging from 0.08mm to 0.2mm and widths customizable from 500mm to 1600mm to meet the structural requirements of heat exchangers. These products are suitable for finning needs in various equipment, including residential air conditioners, commercial central air conditioning systems, and industrial chillers.

Our aluminum fin stock are based on 3003 and 8011 aluminum alloys, achieving a balance between thermal conductivity and corrosion resistance through composition optimization. The 3003 alloy aluminum foil boasts a thermal conductivity of 202 W/(m·K), reducing costs by 30% compared to traditional copper-based materials while improving thermal efficiency by 15%. In terms of corrosion resistance, 8011 O aluminum foil, after anodizing, forms a dense oxide film on its surface. It shows no corrosion spots after a 500-hour neutral salt spray test (GB/T10125-2012), extending its lifespan by more than three times compared to untreated aluminum foil. This characteristic makes it particularly outstanding in air conditioning systems in high-humidity coastal environments or the chemical industry.

Improved heat exchange efficiency is the core competitiveness of our aluminum fin stock products. Haomei Aluminum use a quadruple rolling mill to achieve precise thickness control of 0.08-0.20mm, with a thickness tolerance ≤±1.5μm, ensuring uniform fin spacing after stamping. Experimental data shows that fins stamped with 0.1mm thick aluminum foil have a 22% lower ventilation pressure drop ratio (ΔPw/ΔPd) than 0.15mm products, significantly improving heat exchange efficiency.

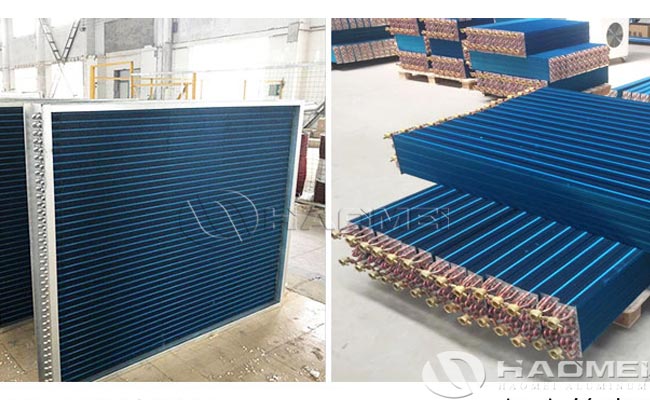

aluminum fin stock for hvac industry

In third-party testing, heat exchangers using our aluminum foil achieved an air-side heat transfer coefficient of 65W/(m²·K), saving 8%-12% more energy than equipment using conventional products under the same operating conditions. To address the issue of condensate bridging causing airflow blockage in air conditioner condenser fins, our company has developed hydrophilic coated aluminum fin stock. This coating results in a water contact angle of ≤10°, allowing condensate to spread and slide off quickly, increasing airflow by 8% compared to ordinary aluminum foil. After accelerated aging testing (85℃/85%RH/500h), the coating adhesion maintained ISO 2409 standard level 0 (no peeling in the cross-cut test).

Furthermore, the lightweight nature of aluminum fin stock offers significant advantages in installation and maintenance. Compared to other metal materials, aluminum has a lower density, reducing the overall system weight and simplifying transportation and installation. Simultaneously, the rational structural design of the aluminum fins facilitates disassembly and cleaning, reducing maintenance costs and improving system reliability.

Application demonstration of Haomei aluminum fin stock for HVAC system:

In the residential air conditioning sector: A certain brand of inverter air conditioner, after adopting our 0.12mm thick hydrophilic aluminum foil, experienced a 5% increase in cooling capacity and an Energy Efficiency Ratio (EER) of 3.6, exceeding the national standard for Grade 1 energy efficiency by 8%.

Industrial cold storage systems: Under -30℃ low-temperature conditions, the 8011 alloy aluminum foil finned evaporator operated continuously for 3 years without corrosion or leakage, extending the maintenance cycle by 2 times compared to traditional galvanized steel finned evaporators.

New energy vehicle heat pump air conditioning: Through joint development with OEMs using 0.09mm ultra-thin aluminum foil, heat exchanger weight was reduced by 15%, contributing to a 3% increase in vehicle range.

When selecting heat dissipation materials for HVAC systems, aluminum fin stock is undoubtedly a wise choice. High-quality aluminum foil is key to improving the energy efficiency of HVAC systems. Its excellent thermal conductivity, corrosion resistance, lightweight characteristics, and environmental advantages make it stand out among many materials. In market competition, our aluminum fin stock has won the trust of many customers with its superior performance and stable quality. Our company always focuses on optimizing material performance and, through precise process control, provides customers with aluminum foil products that combine high-efficiency heat exchange and long-term durability, providing a solid guarantee for energy-saving upgrades in HVAC systems.