11 micron aluminium foil is a common aluminum foil material, with a thickness of 11 microns (0.011 millimeters). Due to its excellent barrier properties, thermal conductivity, and plasticity, 11 micro aluminum foil is widely used in food packaging, pharmaceutical packaging, preservation, cooking, and baking.

11 micron aluminium foil has good flexibility, making it easy to fold, roll, and shape, while also possessing a certain strength, resisting external forces to a certain extent without being easily damaged. It also has excellent moisture-proof, airtight, and light-blocking properties, effectively blocking moisture, oxygen, and light, protecting packaged items from external environmental influences. Furthermore, aluminum foil has good thermal and electrical conductivity, and is non-toxic, odorless, and meets food hygiene standards.

Common alloys of 11 micron aluminium foil:

Common alloys include 8011, 1235, 1100 and 3003. Different aluminum alloys have slightly different properties and are suitable for different application scenarios.

High strength, good puncture resistance, stable processing performance, suitable for food packaging (such as potato chip bags, retort pouch inner layers) and pharmaceutical blister packaging.

– 1235 aluminum foil:

High purity (aluminum content ≥99.35%), excellent flexibility, suitable for flexible packaging composite layers (such as aluminum-plastic layers in milk cartons) and household kitchen aluminum foil.

– 3003 aluminum foil:

Contains manganese, corrosion resistance is better than pure aluminum, has a certain strength, suitable for industrial moisture-proof packaging (such as electronic components, precision parts) and air conditioner heat sinks.

Core performance parameters of 11 micron aluminium foil:

- Mechanical properties

– Tensile strength:

Varies significantly between aluminum alloys. The tensile strength of 8011 aluminum alloy is typically 130-180 MPa, while that of 1235 aluminum alloy is 110-150 MPa. Higher strength is more suitable for packaging scenarios requiring tensile strength (such as automatic packaging machines).

– Elongation:

The elongation of 8011 alloy is approximately 2%-5%, and that of 1235 alloy is approximately 3%-6%. Higher elongation aluminum foil is easier to shape and suitable for folding or deep drawing.

- Barrier properties

– Oxygen transmission rate:

Under conditions of 23℃ and 65% relative humidity, the oxygen transmission rate of 11 micron aluminum foil is almost 0, far superior to plastic films (such as PET film, approximately 5-10 cc/(m²・24h)).

– Water vapor transmission rate:

Under the same conditions, its water vapor transmission rate is less than 0.1 g/(m²・24h), effectively preventing the contents from becoming damp or losing moisture.

- Surface properties

– Surface tension:

Untreated aluminum foil has a low surface tension, approximately 30-35 mN/m. For printing or coating, it needs to be increased to above 40 mN/m through corona treatment to ensure strong adhesion of inks or coatings.

– Surface cleanliness:

Food and pharmaceutical grade aluminum foil requires controlled surface oil content, typically requiring less than 5mg of oil per square meter to avoid contaminating the contents.

Applications of 11 micron aluminium foil:

Widely used in food packaging, it can be used for sandwiches, baked goods, leftovers, etc., and can also be made into composite packaging materials for chocolate, yogurt, beverages, etc. Furthermore, in pharmaceutical packaging, especially blister packaging, 11-micron aluminum foil provides moisture-proof, light-proof, and tamper-evident protection for pharmaceuticals.

Processing technology and surface treatment:

The processing and surface treatment of 11 micron aluminium foil directly change its function. Three common methods are as follows:

– Lamination process:

Composite with plastic films (such as PET, PE) or paper to form an “aluminum foil + substrate” composite film. This retains the barrier properties of aluminum foil while compensating for its fragility. Commonly used in snack packaging bags and pharmaceutical aluminum-plastic composite panels.

– Coating treatment:

Anti-corrosion Coating: Coated with epoxy resin or acrylic resin to improve acid and alkali resistance, suitable for packaging acidic beverages or cosmetics.

Heat-sealing coating: A heat-sealing adhesive is applied, which, when heated, bonds with other materials. Suitable for the sealing process in automatic packaging machines.

– Embossing:

Fine lines or patterns are pressed onto the surface, increasing the aluminum foil’s friction to prevent slippage during stacking and enhancing its appearance. Commonly used in household kitchen aluminum foil or gift packaging.

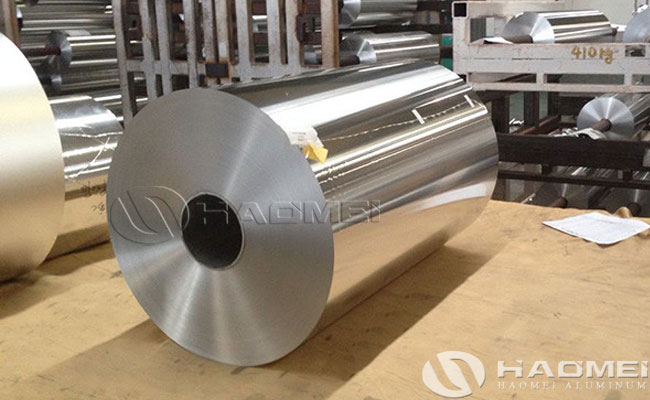

The price of 11 micron aluminium foil varies depending on alloy material, specifications, and manufacturer. When purchasing, in addition to thickness (11μm), the width (commonly 600mm, 1000mm, 1250mm) and length (purchased by roll, with each roll weighing from 50kg to 500kg) must be specified. Custom widths require customization, which will increase production costs and delivery time.