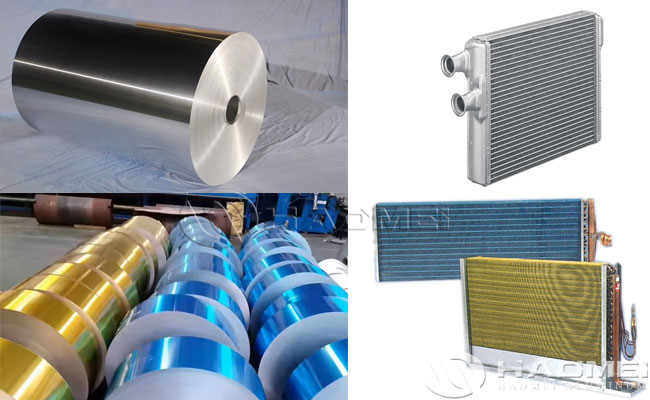

In optimizing the heat exchange efficiency of air conditioning systems, the selection of materials and process design for evaporator aluminum foil remains a core issue. As a technology-driven manufacturer deeply rooted in aluminum foil manufacturing, we use 8011 aluminum alloy as the base material and have built a product matrix covering residential, commercial, and special air conditioning scenarios through dual-track R&D of uncoated and hydrophilic coatings.

With its unique composition design (Fe 0.6-1.0%, Si 0.5-0.9%), 8011 aluminum foil maintains the lightweight advantage of aluminum (density 2.7g/cm³) while increasing tensile strength to 125-165MPa and yield strength to 110MPa through solid solution strengthening. This balance between strength and plasticity allows it to maintain excellent stamping formability within a thickness range of 0.095-0.20mm, making it particularly suitable for the complex flanged structures of evaporator fins.

The choice of heat treatment temper directly affects material properties: H22 (1/4 hard) achieves the best match between strength and ductility through 30% cold rolling deformation, becoming the mainstream choice for evaporator aluminum foil; H24 (1/2 hard) improves fatigue resistance through 50% cold rolling deformation, suitable for high-frequency start-stop variable frequency air conditioning systems. Actual measurement data shows that 8011-H22 aluminum foil, at a thickness of 0.11mm, can achieve an elongation of 8%, fully meeting the requirements of punching and flanging processes.

Uncoated aluminum foil for air conditioner occupies 60% of the market due to its cost advantage, but its surface oxide layer easily generates Al(OH)₃ powder in humid environments, leading to a 15%-20% increase in ventilation resistance. Our developed hydrophilic coated aluminum foil, treated with nano-level silane coupling agents, forms a honeycomb-like hydrophilic film layer on the surface, reducing the water droplet contact angle from 90° to below 25°. This structure allows condensate to spread evenly into a 0.1mm thick water film, reducing air resistance by 80% compared to traditional water droplet formations and improving heat exchange efficiency by 12%-15%.

Coating durability testing shows that after 5000 hours of continuous operation at 85℃/85%RH, the hydrophilic layer remains intact, and no corrosion points were observed after 480 hours of salt spray testing (5% NaCl solution). This performance breakthrough has enabled the hydrophilic coated aluminum foil to successfully penetrate the high-temperature and high-humidity markets of the Middle East and Southeast Asia, with customer test data showing an increase in air conditioner lifespan of over 30%.

In split-type air conditioner evaporators, the combination of 0.11mm thick 8011-H22 hydrophilic aluminum foil and internally threaded copper tubing increases the heat exchange area by 25%. Combined with a 2.5m/s face velocity design, energy consumption per unit cooling capacity is reduced by 8%. For precision air conditioning in data centers, 0.095mm ultrathin aluminum foil, through optimized grain orientation (average grain size <20μm), reduces fin spacing to 1.2mm, achieving a 40% improvement in heat exchange capacity within the same volume.

Notably, the added value brought by the hydrophilic coating is becoming apparent: tests by an automotive air conditioning manufacturer showed that after using hydrophilic aluminum foil, the mold growth rate on the evaporator surface decreased by 92%, and complaints about air conditioning odor decreased by 75%. This comprehensive improvement from heat exchange efficiency to air quality is redefining the technical standards of high-end air conditioning products.

From uncoated to hydrophilic coatings, from single heat conduction to system optimization, the technological evolution of aluminum foil for air conditioning evaporators has always revolved around the core requirements of “efficiency-reliability-health.” Through composition optimization of 8011 aluminum alloy, nano-scale modification of coating processes, and customized development for different scenarios, we have built a product system covering a thickness range of 0.095-0.20mm and multiple states (H22/H24/H26) for selection. This technological depth and responsiveness are key to aluminum continued rise in the global air conditioning industry chain.