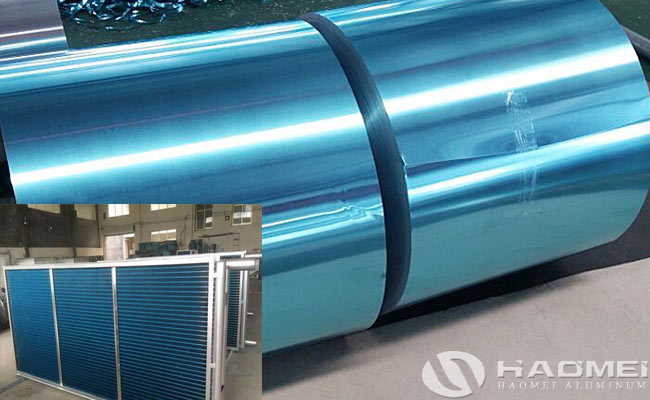

Haomei supply high quality aluminum foil for heat transfer for sale, the heat exchange efficiency is high and the noise is low during use. When hydrophilic aluminum foil is used as a heat exchanger, its coating properties such as adhesion, corrosion resistance and hydrophilicity are required during processing and use. Aluminum fin stocks are made of aluminum foil. The usual way to treat the surface of aluminum fins is to apply a hydrophilic treatment on the surface of the aluminum foil, that is, to cover the surface of the aluminum foil with a hydrophilic coating, and then apply anti-corrosion treatment on the hydrophilic coating, including covering Anticorrosive inorganic coating or organic resin coating to form a double-layered film structure, so that the aluminum foil has corrosion resistance and hydrophilicity.

With the continuous popularization of air-conditioning applications, in order to achieve energy saving of air-conditioning and other purposes, research on air-conditioning heat exchangers is also ongoing. The existing technological innovations are concentrated on the aluminum fins of the heat exchangers. For example, by optimizing the shape of aluminum fins, thinning of aluminum fins, and improvement of the properties of aluminum fins through surface treatment can improve the heat exchange efficiency of the heat exchanger, so as to achieve energy saving and improve the heat exchange effect of air conditioners.

The surface of hydrophilic aluminum foil for air container has strong hydrophilicity. The hydrophilicity is determined by the angle formed by the water sticking to the surface of the aluminum foil. The smaller the angle , the better the hydrophilic performance, and vice versa, the worse the hydrophilic performance. Generally speaking, angle is less than 35. It belongs to hydrophilic properties. Hydrophilic aluminum foil is generally used on condensers of air conditioners. Its main function is to make the moisture in the hot air easy to spread out when condensed into water droplets on the heat exchange fins and flow down along the sheet. This can prevent the water droplets between the heat exchange fins from affecting the ventilation effect of the heat exchanger, thereby increasing the heat exchange rate of the air conditioner, and saving electricity under the same cooling capacity. At present, the general hydrophilic aluminum foil for heat transfer on the market not only has better hydrophilicity on the surface, but also has higher corrosion resistance, so that the performance of the air conditioner is more optimized.