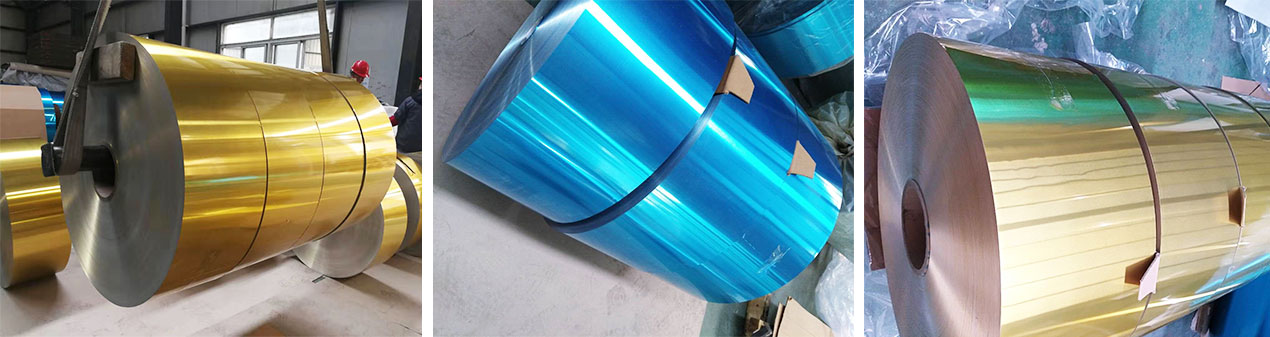

Coated aluminum foil for HVAC uses is an aluminum foil material that has been given special functions through surface treatment technology. It is mainly used in the manufacture of fins for air conditioner heat exchangers (such as evaporators and condensers) to improve the performance of the entire machine and adapt to a variety of usage scenarios. Coated aluminum foil has important applications in heating, ventilation and air conditioning (HVAC) systems.

Functions and application scenarios of coated aluminum foil for HVAC uses:

- Improve heat exchange efficiency

– Hydrophilic aluminum foil: The surface is coated with a hydrophilic coating (such as silicone or surfactant) to make the condensed water form a contact angle of less than 35° on the surface of the aluminum foil, quickly spread into a water film and flow down along the fins to avoid water droplets blocking the channel, which can increase the heat exchange rate by 5%. This type of aluminum foil is widely used in air conditioner evaporators, especially in high humidity environments.

– Hydrophobic aluminum foil: By increasing the contact angle (usually > 75°), the condensed water forms water droplets that are easy to slide off, which is suitable for specific scenarios where surface water accumulation needs to be reduced.

- Enhance corrosion resistance

Anti-corrosion coatings (such as epoxy resins or ceramic materials) can resist erosion by salt spray, alkaline cleaning agents, etc. For example, the salt spray test requires no corrosion spots for 500 hours in a 3% salt spray environment, which is particularly suitable for coastal areas with high humidity.

- Other functions

– Anti-mildew aluminum foil: used for indoor units, inhibits mold growth and improves air quality.

– Self-lubricating aluminum foil: pre-coated with a lubricating film on the surface, eliminating the lubricating oil and subsequent cleaning process during processing, which is environmentally friendly and reduces costs.

Technical characteristics and standards of coated aluminum foil for HVAC uses:

- Coating performance indicators

– Hydrophilic performance: initial contact angle < 10°, < 25° after environmental resistance test, tested by contact angle meter or water drop area method.

– Adhesion: It is necessary to pass the cross-cut test, abrasion resistance test, etc. to ensure that the coating does not fall off.

– Alkali resistance: Soak in 20% NaOH solution for 3 minutes without bubbling to withstand the processing and cleaning process.

- Materials and processes

– Base material: Mainly 1100, 1200, 8011 and other aluminum alloys, the thickness has been reduced from the early 0.15-0.2mm to the current 0.09-0.15mm, taking into account both lightweight and strength.

– Production process: including degreasing, passivation pretreatment → roller coating / spray coating → curing (such as baking at 180-220℃), the plate shape needs to be controlled within 20-40I to avoid production wrinkles.

- Industry standards

– Hydrophilic aluminum foil must comply with the YS/T95.2-2001 standard, and there are strict requirements for chemical composition, mechanical properties (tensile strength, elongation) and coating uniformity.

Market and technology trends of coated aluminum foil for HVAC uses:

– Proportion: Hydrophilic aluminum foil accounts for more than 80% of the total aluminum foil used for air conditioners, and is widely used in variable frequency air conditioners and high-end models.

– Ultra-thin and high-strength: The thickness continues to decrease to below 0.09mm, and the anti-stamping performance is improved through alloy optimization and coating enhancement.

– Environmentally friendly coating: New materials such as graphene coating have begun to be studied, which have both high thermal conductivity and anti-corrosion properties and may replace traditional organic coatings in the future.

– Process innovation: For example, the passivation-free treatment technology reduces the use of chemicals and complies with the trend of environmental protection regulations.

Advantages of coated aluminum foil for HVAC uses:

– Energy saving and efficiency improvement: Improving heat exchange efficiency can reduce air conditioning energy consumption and save electricity under the same cooling capacity.

– Extended life: Anti-corrosion coating prolongs the service life of air conditioners in harsh environments and reduces maintenance costs.

– Environmentally friendly and safe: Self-lubricating aluminum foil avoids trichloroethylene cleaning pollution, and anti-mildew coating improves indoor air quality.

Through the above characteristics, coated aluminum foil has become a key material for modern HVAC uses to achieve high efficiency, durability and environmental protection. With the iteration of technology, its performance and application scenarios will be further expanded.