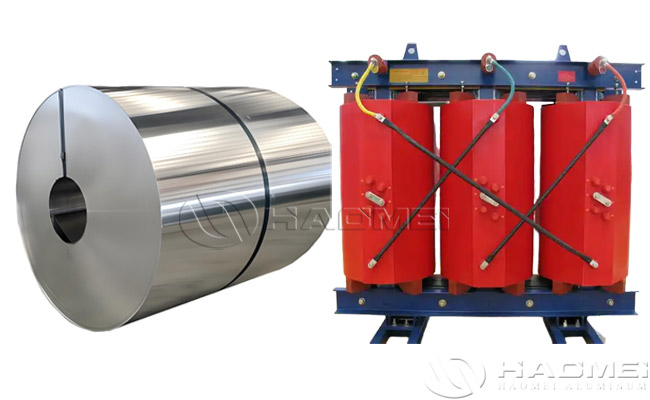

Aluminum foil is widely used in transformer windings due to its excellent conductivity and lightweight properties. Transformer winding aluminum foil usually uses aluminum foil with a thickness ranging from 0.1mm to 0.5mm, and the width can be determined according to the transformer design requirements, generally between 20mm and 200mm. Aluminum foil has good conductivity, high oxidation resistance and mechanical strength. When used as a transformer winding material, it is necessary to ensure that its surface is smooth and scratch-free to reduce electrical losses and improve the performance of the transformer. In addition, the purity of aluminum foil for transformer winding is usually above 99.5% to ensure its conductivity and durability.

The main reason for using aluminum foil in transformer windings is its unique physical, chemical and economic properties, which give it significant advantages in specific scenarios. The following are the advantages of using aluminum foil in transformer windings:

- Cost advantage

– Low material cost:

The unit price of aluminum is much lower than that of copper (aluminum is about 1/3 of copper). Under the same electrical performance requirements, using aluminum foil instead of copper wire or copper foil can significantly reduce the manufacturing cost of the transformer.

– Outstanding economic efficiency:

Especially in large-capacity transformers, the low-cost advantage of aluminum is more obvious, which is suitable for budget-sensitive application scenarios (such as residential and commercial buildings).

- Lightweight

– Lightweight design:

The density of aluminum is about 1/3 of that of copper (2.7 g/cm³ vs. 8.9 g/cm³). The use of aluminum foil winding can greatly reduce the overall weight of the transformer, making it easier to transport and install. It is especially suitable for mobile equipment or weight-sensitive scenarios (such as mobile energy storage vehicles, aerospace equipment, etc.).

- Excellent processing performance

– Easy to process:

Aluminum foil has a low hardness, is not easy to produce burrs during processing, and has a smooth surface, which reduces the risk of insulation material being pierced and improves the insulation safety of the transformer.

– Automated production:

The foil winding process can complete winding, welding and wrapping at one time through a fully automatic winding machine, improving production efficiency and product consistency.

- Good heat dissipation performance

– Large heat capacity:

The specific heat capacity of aluminum is higher than that of copper (0.897 J/g·K vs. 0.385 J/g·K). Under the same load, the aluminum foil transformer heats up slowly and allows a longer overload time (such as carrying 2 times the rated current within 1 minute), which is suitable for short-term overload requirements.

– Thermal expansion matching:

The thermal expansion coefficients of aluminum and resin are closer (Al/resin = 24:37, Cu/resin = 17:37), reducing the cracking of the insulation layer or partial discharge caused by temperature difference and extending the life of the transformer.

- Anti-interference ability

– Electromagnetic compatibility:

The compact winding structure and shielding design of the foil-wound transformer can effectively reduce leakage reactance and resistance, reduce electromagnetic interference (EMI), and are suitable for scenes with high power quality requirements in industrial environments (such as data centers and automated production lines).

- Energy saving and environmental protection

– Skin effect optimization: In high-frequency applications, the cross-sectional area of the aluminum foil can be designed to be smaller (through the foil winding process) to reduce the increase in resistance caused by the skin effect. For example, at a frequency of 200 kHz, the resistance of a 1 mm copper wire is twice that of a copper foil with the same cross-section, while aluminum foil has a higher transmission efficiency.

– Energy saving and emission reduction:

Lower energy loss and lightweight design are in line with modern green energy trends.

- Design flexibility

– Adapt to complex structures:

Aluminum foil can be processed into different thicknesses (6-30 μm) and widths (15-55 mm), which is convenient for designing compact transformers, especially for applications with limited space.

– Diversified packaging:

It can be combined with resin potting, air gap design and other processes to improve the mechanical strength and environmental adaptability of the transformer.

- Wide range of applicable scenarios

– Cost-effective scenarios:

Such as residential power distribution, commercial buildings, emergency power supplies and other cost-sensitive fields.

– Special demand scenarios:

Mobile energy storage vehicles, electric vehicle charging stations and other equipment that require lightweight and short-term overload capacity.

– High-frequency equipment:

Switching power supplies, high-frequency inverters and other occasions that are sensitive to skin effect.

Aluminum foil winding transformers have significant advantages in cost, weight, heat dissipation and high-frequency performance, and are especially suitable for scenarios with high requirements for economy and lightweight. However, its design and application need to be combined with specific needs, weighing factors such as conductivity, connection reliability and environmental adaptability. With the advancement of process technology, the application prospects of aluminum foil transformers in new energy, smart grid and other fields will be broader.