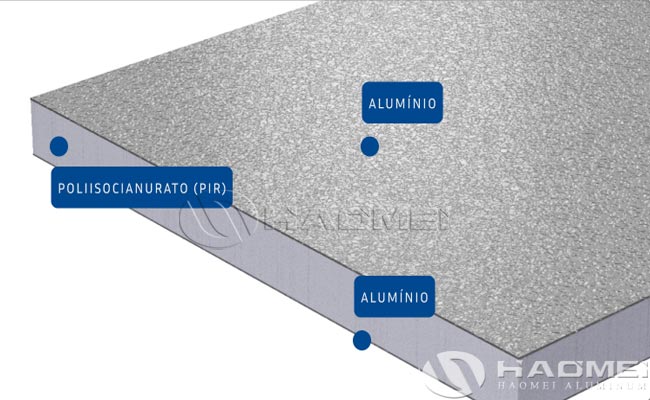

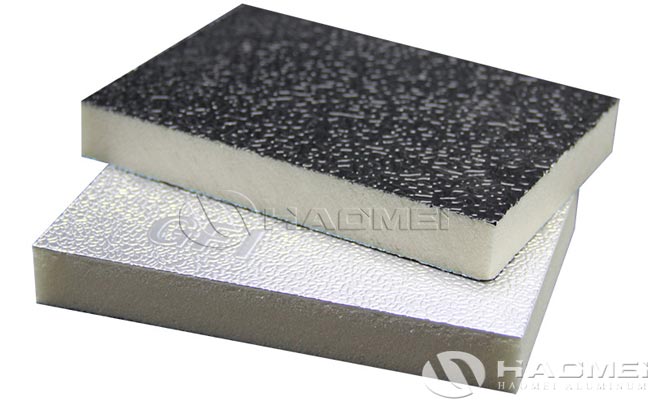

Aluminum foil for PIR insulation panels primarily enhances performance, improves thermal insulation and protects the material. PIR insulation panels have a “sandwich” structure, with aluminum foil serving as a double- or single-sided covering layer, laminated to the PIR foam core.

Aluminum Foil Thickness and Types

– Standard Thickness: Common aluminum foil thicknesses range from 0.04-0.08mm (80 microns) and are used for general-purpose air ducts.

– Enhanced Configuration: In locations susceptible to external damage (such as shopping malls and airports), the outer layer may be upgraded to 0.22mm aluminum alloy sheet, while the inner layer retains 0.08mm aluminum foil, achieving both strength and insulation.

– Special Treatment: The inner layer of aluminum foil is often cleaned and coated with glue to improve adhesion to the PIR foam. The outer layer can also be embossed (e.g., embossed aluminum foil) to enhance scratch resistance.

The core role of aluminum foil in PIR insulation board

- 1.Reflecting thermal radiation and enhancing thermal insulation performance

Principle: Aluminum foil has a high reflectivity (up to 90%) and can reflect external thermal radiation (such as sunlight, ambient heat source) back, reducing heat transfer to the interior of the insulation material.

Effect: Reduce the heat load on the building exterior wall or pipe surface and improve the overall insulation efficiency. For example, in the air conditioning duct system, aluminum foil can reduce cooling loss.

- Moisture-proof and waterproof, extending service life

Moisture-proof: Aluminum foil acts as a barrier layer to effectively prevent water vapor from penetrating into the PIR foam core material, avoiding the material from being damp and causing performance degradation.

Waterproof: Combined with a waterproof membrane or closed-cell structure (such as the closed-cell rate of PIR itself >95%), it forms a double protection, suitable for high humidity environments (such as cold storage, cold chain logistics).

- Enhance mechanical strength and structural stability

Compression/tensile properties: The aluminum foil layer can increase the surface hardness of the PIR board and reduce deformation or damage during transportation and installation. Dimensional Stability: The combination of aluminum foil and PIR foam inhibits the material’s shrinkage or expansion under temperature fluctuations, maintaining dimensional stability.

- Improved Fire Resistance

Fire Resistance Rating: PIR itself achieves Class B1 flame retardancy, while aluminum foil, as a Class A non-combustible material, further enhances the fire safety of the composite panel. It is suitable for applications requiring high safety standards, such as building exterior wall insulation and duct systems.

Applications of aluminum foil PIR insulation board:

– Building Insulation: Exterior walls, roofs, and sandwich walls, particularly suitable for energy-saving buildings and cold regions.

– Air Conditioning Duct Systems: Low-pressure air conditioning ducts and rail transit vehicle ventilation systems use aluminum foil to reduce cooling loss.

– Cold Chain and Refrigerated Storage: Cold storage and fresh food transport packaging use aluminum foil + foam layers for dual insulation, extending shelf life.

– Industrial Equipment Insulation: Insulating pipes and storage tanks prevents heat loss and condensation.

The combination of aluminum foil and PIR insulation board significantly improves the overall performance of the insulation system by reflecting heat radiation, resisting moisture and water, enhancing structural strength, and improving fire resistance. Its application in building energy conservation, cold chain logistics, industrial insulation and other fields embodies the advantages of high efficiency, safety and environmental protection.