Aluminum fin stock foil is the material used for the fins in air conditioners and is typically made from aluminum alloy. Aluminium foil offers excellent thermal conductivity, corrosion resistance and lightweight properties, making it widely used in air conditioner heat exchangers. The fin design increases the contact area between air and coolant, thereby improving heat transfer efficiency.

Air conditioner fin stock aluminum foil is not pure aluminum, but rather has its properties modified by the addition of specific alloying elements (such as Mn, Si, and Fe). Different grades are designed for different applications, with key differences reflected in thermal conductivity, strength, and corrosion resistance.

– 1100 Aluminum Foil

Pure aluminum (Al ≥ 99.0%) has a thermal conductivity of 220 W/(m・K) and a tensile strength of 70-110 MPa. It offers excellent thermal conductivity, good ductility, and low cost, making it suitable for mid- and low-end air conditioner evaporators/condensers where strength requirements are less demanding.

Al-Mn (Mn 1.0-1.5%) alloy, thermal conductivity 190W/(m・K), tensile strength 110-150MPa, strong corrosion resistance (better than 1100), moderate strength, suitable for humid environments and commercial air conditioners (requiring long-term resistance to condensation water corrosion).

Al-Fe-Si (Fe 0.7-1.3%, Si 0.5-1.0%) alloy, thermal conductivity 180W/(m・K), tensile strength 120-160MPa, high strength, strong deformation resistance, and good processability (not prone to breakage during stamping). Suitable for ultra-thin fins (thickness ≤ 0.1mm) and high-end household air conditioners (pursuing lightweight and high strength).

– Thickness:

Generally between 0.09-0.2mm. With the advancement of air conditioning technology, fin stock aluminum foil has been trending towards ultra-thinness. For example, in the 1980s, heat exchanger fins were 0.15-0.2mm thick, but today, thicknesses mostly range from 0.09-0.15mm.

– Width:

Common widths range from 100-1600mm, and can be customized to meet the needs of different air conditioning heat exchangers.

Air conditioning fin stock aluminum foil can be divided into two categories based on coating type: uncoated and coated. Coated aluminum foil is further subdivided into various functional coatings to meet different environmental and application requirements.

- Uncoated Aluminum Foil

Aluminum foil without any surface treatment is produced through rolling and annealing. It has a silvery-white surface and lacks corrosion resistance or hydrophilic properties. It is low-cost, but has poor corrosion resistance and is prone to forming “water bridges.”

Applications: Currently, it is rarely used, primarily in cost-sensitive international markets or specific scenarios.

- Coated Aluminum Foil:

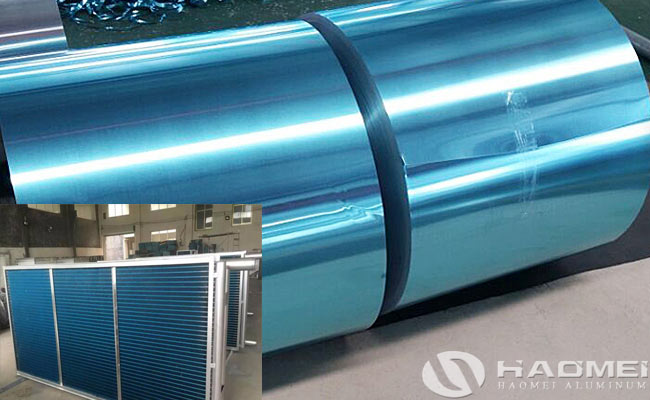

Uncoated aluminum foil is surface-treated to impart special features. For example, corrosion resistant aluminum foil has a protective layer against corrosion, making it suitable for harsh environments. Hydrophilic coated aluminum foil, with its strong affinity for water, is used in air conditioner evaporators to improve heat exchange efficiency. Coatings are available in blue, gold, and black. Hydrophobic aluminum foil repels water, allowing condensed water to bead up and slide off. Self-lubricating aluminum foil eliminates the need for separate lubrication during punching. Mildew-resistant aluminum foil is primarily used in air conditioner indoor units to prevent mold on heat exchangers.

Production Process of Aluminum Fin Stock Foil:

It typically includes smelting, casting, rolling, annealing, and surface treatment. First, high-purity aluminum ingots are smelted with other alloying elements, then cast into billets. These billets are then rolled into foil of the desired thickness through multiple rolling processes. Finally, annealing is performed as needed to improve the foil’s performance. Some foils also require surface treatments such as coatings.

Features of Aluminum Fin Stock Foil:

– Excellent Thermal Conductivity:

Aluminum’s high thermal conductivity allows for rapid heat transfer, improving the heat exchange efficiency of air conditioners.

– Low Density:

The lightweight material reduces the overall weight of the air conditioner, making it easier to install and transport.

– Easy to Process:

With excellent ductility and plasticity, it can be formed into various fin shapes through processes such as stamping and rolling.

– Environmentally Friendly and Odorless:

Aluminum is an environmentally friendly material that is non-toxic, odorless, and harmless to humans and the environment.

– Affordable:

Compared to other metals, aluminum is more affordable, which can reduce the production cost of air conditioners.

Aluminum foil for air conditioner fins is a key component for heat exchange in air conditioning systems. Typically made of aluminum or aluminum alloy, it performs the following core functions:

– Increased Heat Exchange Area:

Structural designs such as corrugations and serrations significantly increase the contact area with the air or refrigerant, improving heat transfer efficiency.

– Optimized Fluid Flow:

Special shapes (such as spirals and corrugations) guide fluid turbulence, disrupt boundary layers, and enhance convective heat transfer.

– Corrosion Resistance and Hydrophilicity:

Surface coatings (such as hydrophilic and anti-corrosion coatings) prevent condensation accumulation, reduce corrosion, and extend service life.

– Lightweight and Cost Advantages:

Aluminum has low density, good thermal conductivity, and is cheaper than copper, making it suitable for large-scale residential and industrial applications.

Major Applications of Aluminum Fin Stock Foil:

– Residential/commercial air conditioners:

Evaporator and condenser fins improve cooling/heating efficiency and reduce energy consumption.

– Automotive air conditioners:

Driven by lightweighting demands, aluminum foil fins are replacing traditional copper in the thermal management systems of new energy vehicles.

– Industrial cooling systems:

Such as chemical heat exchangers and desalination equipment, utilize corrosion-resistant aluminum foil to withstand harsh environments.