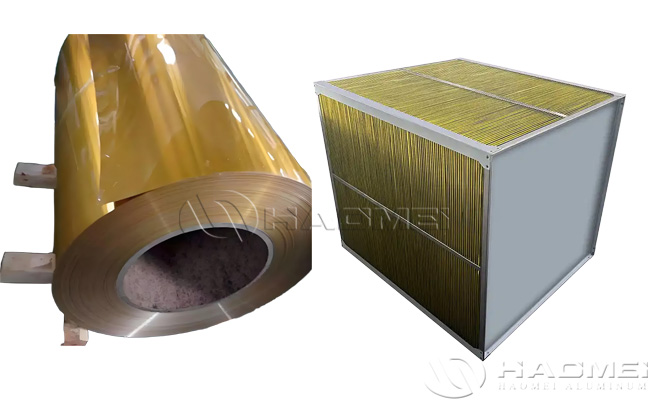

Gold color aluminum fin stock for heat exchangers typically refers to a specially treated aluminum material used in heat exchangers, primarily to improve heat exchange efficiency. This material not only offers excellent thermal conductivity but also possesses hydrophilicity, which contributes to improved heat exchange efficiency. The hydrophilic treatment creates a coating on the aluminum fin stock surface that absorbs water molecules, increasing the contact area with the fluid, improving heat transfer performance, enhancing corrosion resistance, and optimizing condensate management.

Specification of Gold Color Aluminum Fin Stock For Heat Exchangers:

– Common aluminum alloy grades:

Include 8011-O (annealed) and 3102-H24 (work-hardened). 8011-O aluminum fin stock offers excellent formability and corrosion resistance, making it suitable for complex fin stamping. 3102-H24 aluminum fin stock offers increased strength and is suitable for high wind pressure environments.

– Coating Thickness:

The gold coating thickness per side is typically 1.2-2.0μm, depending on the corrosive environment (e.g., ≥1.5μm is recommended for coastal areas).

– Temperature Resistance:

Epoxy resin coatings can withstand temperatures up to 200°C, while standard acrylic coatings are recommended to be ≤100°C.

– Processing:

Coating adhesion after fin formation must be verified. For example, the coating should not fall off after the expansion test.

Core Performance of Gold Color Aluminum Fin Stock For Heat Exchangers:

– Improved Heat Exchange Efficiency:

The hydrophilic coating allows condensed water to quickly spread onto the fin surface into a uniform film, preventing “water bridging” caused by condensation. This reduces air flow resistance and improves heat exchange efficiency by 5%-10%. The fin evaporator maintains stable heat transfer performance even under high-temperature conditions, making it suitable for demanding heat dissipation requirements in data centers and other environments.

– Corrosion Resistance and Long Life:

The protective gold coating on the surface of aluminum fin stock significantly extends the life of the heat exchanger. It performs exceptionally well in salt spray tests and withstands chemical corrosion in industrial environments. It has passed a 30-minute extreme acid resistance test and showed no significant corrosion after 1000 hours of simulated aging, far exceeding traditional silver or blue fins.

– Environmental Protection and Easy Maintenance:

The coating contains no harmful substances such as chromates and is RoHS compliant. Some products can be rinsed directly with tap water, reducing maintenance costs. Furthermore, the coating inhibits mold growth and prevents odor.

Typical Applications of Gold Color Aluminum Fin Stock:

Widely used in air conditioners, refrigeration equipment, heat exchangers, and other applications. Hydrophilic fins, particularly in water-cooling systems, significantly improve heat exchange efficiency.

– Residential and commercial air conditioners:

Gold hydrophilic aluminum fins are widely used in condensers and evaporators, improving energy efficiency and reducing noise.

– Industrial heat recovery systems:

Epoxy resin-coated products are suitable for high-humidity and high-temperature environments such as drying and printing, and can withstand operating temperatures exceeding 200°C.

– Data centers:

The aluminum foil core, through enhanced stamping technology, has a pressure resistance of 2500Pa, meeting the heat dissipation requirements of precision equipment.

– Automotive air conditioners:

Gold hydrophilic aluminum foil based on 8011-O substrate is the preferred choice for automotive heat exchangers due to its lightweight and corrosion resistance.

The price of gold color aluminum fin stock for heat exchangers is 15%-30% higher than that of ordinary aluminum foil stock, depending on the coating process and substrate thickness. The lead time for regular orders is 7-15 days, and customized specifications (such as special width or temperature resistance requirements) will be extended to 20-30 days.