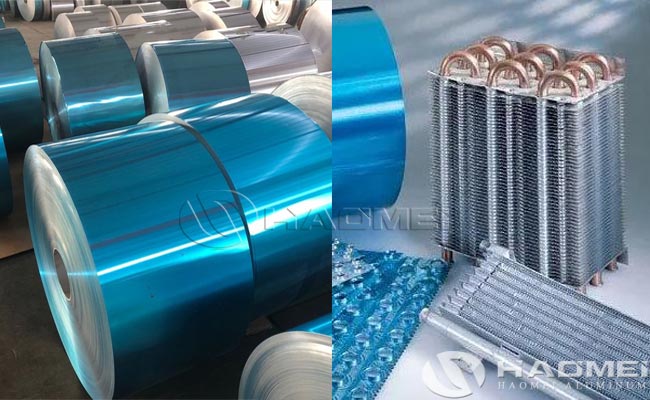

Hydrophilic coated aluminum fin stock for air conditioners are primarily made from aluminum foil with hydrophilic coating. This coating layer is applied to the surface of the aluminum foil by special process, imparting excellent hydrophilic properties and enhancing air conditioner performance.

Common alloy grades of hydrophilic coated aluminum fin stock:

– 3102: Aluminum foil in the 3102H26 state offers excellent overall performance and is commonly used for heat sinks in air conditioners.

– 8011: Aluminum foil in the 8011H24 state is a commonly used alloy for hydrophilic aluminum foil, offering excellent hydrophilicity and processing properties.

Specifications of hydrophilic coated aluminum fin stock:

– Thickness: Generally between 0.085-0.20mm.

– Width: Common widths range from 270-1100mm.

– Inner Diameter: Common sizes include φ150mm and φ200mm.

Hydrophilic coating is the core technology of hydrophilic coated aluminium foil. Its composition, structure, and coating process directly influence its hydrophilicity, corrosion resistance and durability. Currently, the industry’s mainstream coating method is inorganic-organic composite coating. Roller coating is the most commonly used process, where the coating liquid is evenly transferred to the aluminum foil surface via a coating roller and then cured in a drying oven (180-220°C). The coating thickness is controllable (±0.5μm), and production efficiency is high (speeds can reach 300-500 m/min), making it suitable for large-scale mass production.

Features of hydrophilic coated aluminum fin stock for air conditioners:

– Hydrophilicity:

The hydrophilic coating increases the surface energy of the aluminum fin, making it more receptive to water absorption, thereby enhancing heat exchange efficiency. This improves heat transfer performance and reduces energy consumption during cooling or heating. It also effectively prevents noise caused by condensation obstructing air flow.

– Corrosion Resistance:

The aluminum fin stock must possess excellent corrosion resistance to withstand the humidity and other corrosive factors found in the air conditioning equipment’s operating environment. A hydrophilic coating often provides additional protection.

– High-Temperature Resistance:

The hydrophilic coating must remain stable in high-temperature environments, preventing degradation or loss of hydrophilicity due to temperature fluctuations.

– Good Adhesion:

The coating must maintain good adhesion to the aluminum fin material to prevent detachment or peeling during use.

– Excellent Formability:

The coating exhibits excellent formability and resistance to mold wear, while also offering strong resistance to stamping oils, solvents, and heat.

– High Heat Exchange Rate:

The coating offers low airflow resistance, generally improving 10%-15% heat exchange rates compared to conventional plain aluminum fin stock.

– Easy to Clean:

Hydrophilic coatings typically have a smoother surface, reducing the adhesion of dirt and scale, making them easier to clean and maintain.

– Environmentally Friendly:

Modern coating materials are increasingly environmentally friendly, with non-toxic and harmless coatings being selected to meet environmental standards.

Hydrophilic aluminum foil is widely used in heat exchanger fins in refrigeration equipment such as residential and commercial air conditioners, central air conditioners, and dehumidifiers. It is the primary raw material for heat exchanger fins in air conditioners.

In short, hydrophilic coated aluminum fin stock for air conditioners plays a vital role in improving the performance and efficiency of air conditioning equipment and is an indispensable material in modern air conditioner design.