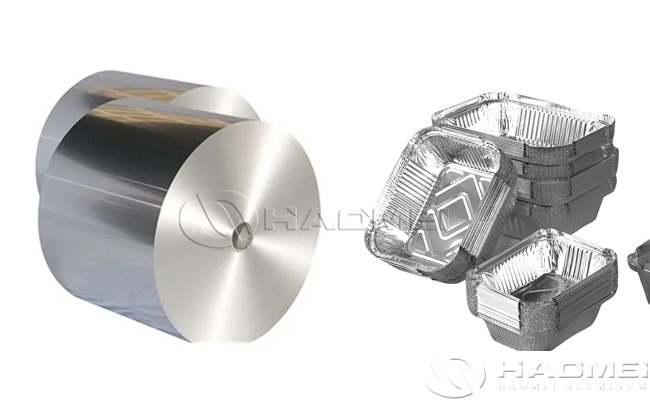

Lubricated aluminum foil for food container is typically made from 8011 or 3003 aluminum alloys, with a thickness ranging from 0.04mm to 0.08mm. A food-grade lubricant (such as DOS oil) is applied to the aluminum foil surface to create a protective layer, reducing friction damage during stamping and improving product yield.

Material Selection of Lubricated Aluminum Foil For Food Container:

– Aluminum Alloy Types

Commonly used aluminum alloys such as 8011 and 3003 offer excellent ductility, strength, and corrosion resistance, making them suitable for stamping into food containers.

– Specifications

Thickness Range: 0.04mm to 0.08mm (can be reduced to 0.06mm in some applications).

Width and Tolerance: Widths typically range from 400mm to 800mm, with a thickness tolerance within ±3% to ensure forming stability.

– Coating Oil

Type: Food-grade lubricant (such as DOS oil) compliant with FDA 21 CFR 178.3910(a) and NSF or FDA 3H/H1 certification.

Features: Excellent lubricity, high flash point, long shelf life, and resistance to deterioration, avoiding the spoilage issues associated with traditional oils (such as animal oil).

Oiling Process of Lubricated Aluminum Foil For Food Container:

– Purpose of Oiling

To form a uniform oil film on the aluminum foil surface, reducing friction between the foil and the die during stamping, preventing scratches, and improving product surface quality.

– Oil Amount Control

Range: The oiling amount applied to one side typically ranges from 80mg/m² to 400mg/m² (on both sides), depending on the molding process requirements.

Precision Requirements: The oiling amount tolerance must be controlled within ±10% to ensure product consistency within the same batch.

Cost-Effectiveness: The oiling process reduces mold wear and product scrap rates, lowering overall production costs.

– Performance Improvement

Formability: The oil coating reduces friction between the foil and the die, increasing stamping speed and demolding efficiency.

Corrosion Resistance: The food-grade lubricant forms a protective layer, extending the life of the aluminum foil container.

Oil lubricated aluminum foil for food containers offers several advantages:

– Excellent barrier properties:

Oil lubricated aluminum foil offers excellent barrier properties against gases, moisture, and light, effectively protecting food quality and extending its shelf life.

– High-temperature resistance:

Oil lubricated aluminum foil withstands high temperatures, making it suitable for baking and heating. It maintains stability and resists deformation in high-temperature environments.

– Lightweight:

Aluminum foil is lightweight, making it easy to transport and use, effectively reducing transportation costs.

– Excellent formability:

Oil lubricated aluminum foil can be easily processed into containers of various shapes and sizes to meet diverse food packaging needs.

– Safety:

Specially treated oil lubricated aluminum foil generally meets food safety standards and poses no harmful effects on food.

– Environmentally friendly:

Aluminum foil is recyclable, aligning with sustainable development and minimizing environmental impact.

Application Scenarios of Lubricated Foil For Food Container:

Main Applications: Food containers for airline catering, high-speed rail fast food, home cooking, and large-scale cake chain stores.

Suitable for baking, freezing, and preserving food, it can be heated directly on a gas stove or in an oven (microwave ovens are prohibited).

Quality Testing and Standards of Lubricated Aluminum Foil For Food Container:

– Coating Performance Testing

Acid and Alkali Resistance Test: Simulates food contact environments to ensure coating stability in acidic or alkaline conditions.

High-Temperature Resistance Test: Tests at 300°C for 25 seconds to ensure no coating flaking or deterioration.

Oil Application Uniformity: Tested using equipment such as a beta-ray thickness gauge to ensure compliance with applicable oil application standards.

– Compliance Requirements:

Complies with EU REACH regulations.

Oil must be FDA or NSF certified to ensure it is non-toxic and harmless.