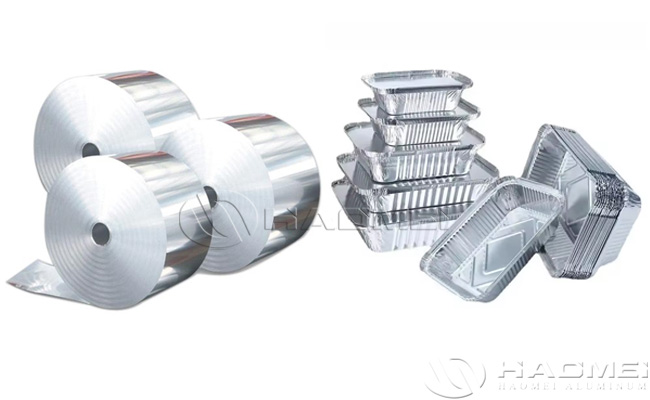

Mill finish aluminum foil is a preferred material for food containers due to its lack of coating residue and excellent corrosion resistance. After special processing, its excellent physical and chemical properties make it widely used in the production of food packaging and containers. The thickness of mill finish aluminum foil for food container generally ranges from 0.006 to 0.2 mm, making it thin yet strong. The surface of aluminum foil can be smoothed, coated, or printed to enhance its barrier properties and visual appeal.

Food containers require aluminum foil to have specific requirements for ductility (ease of stamping), corrosion resistance (no rusting when exposed to acids and alkalis), and strength (no deformation when holding hot food). 3003 and 8011 mill finish aluminum foil meet these requirement, and they each focus on different requirements, meeting the following requirements:

– 3003 aluminum foil for food container:

Contains 1.0%-1.5% manganese (the primary strengthening element) and a small amount of copper.

- Stronger than 8011, resists collapse when holding hot food or heavy objects.

- Excellent corrosion resistance, no corrosion from acidic foods such as vinegar and juice.

- Moderate ductility, allowing for stamping into complex shapes (such as lidded lunch boxes and deep trays).

- Suitable for disposable hot food containers, takeout containers, and reusable food storage containers.

– 8011 aluminum foil for food container

Contains 0.5%-0.9% silicon and 0.6%-1.0% iron.

- Excellent ductility, easily stamped into thin-walled, custom-shaped containers (such as egg tart trays and small cake molds);

- Lower cost than 3003, suitable for mass production of disposable, lightweight containers;

- Highly smooth surface finish, easy to form, and smooth appearance.

- Suitable for making disposable baking molds (egg tart trays, snow meringue trays), individual snack packaging trays, and lightweight cold drink cups.

“H24” and “H22” represent the “work-hardened + partially annealed” state of aluminum foil, which directly affects the material’s hardness and ductility. The choice should be based on the container’s “forming difficulty” and “use intensity”:

H22 temper:

This is a “semi-hard” state with a lower degree of work hardening and improved ductility. It is suitable for food containers requiring complex stamping (such as multi-pleated baking trays and deep-drawn bowl-shaped containers). It easily conforms to mold shapes and is not prone to cracking. Its moderate hardness provides adequate support for daily cold and room-temperature food storage, but avoids excessive hardness that can result in sharp edges after forming.

H24 temper:

This is a “fully hard” temper, with a higher degree of work hardening and a hardness approximately 20%-30% higher than H22. Its advantage is its strong resistance to deformation, making it suitable for holding hot foods (such as meals above 100°C), soupy foods, or containers that need to be stacked (such as takeout containers). It can withstand weight and temperature shock without collapsing or deforming. However, its ductility is slightly lower than that of H22, making it more suitable for simple stamping containers (such as flat plates and shallow trays).

Advantages of mill finish aluminum foil for food container:

– Excellent Barrier Properties:

Aluminum foil offers excellent barrier properties against gases, moisture, and light, effectively preventing the effects of oxygen, moisture, and light on food, thereby extending its shelf life.

– High and Low Temperature Resistance:

Aluminum foil can withstand both high and low temperatures, making it suitable for a variety of applications, including baking, heating, and refrigeration. It does not release harmful substances at high temperatures, making it widely used in baked goods packaging.

– Lightweight and Flexible:

Aluminum foil is thin and easy to form, allowing it to be made into a variety of shapes to suit different food packaging needs.

– Recyclability:

Aluminum foil is a recyclable material, aligning with modern environmental trends. Recycling aluminum foil can save significant energy and resources.

– Damage-Resistant:

Aluminum foil resists damage during packaging, effectively protecting food during transportation and storage.

Mill finish aluminum foil has a wide range of applications in food containers, including but not limited to:

– Aluminum foil lunch boxes:

Commonly used in takeout and fast food restaurants, they conveniently hold both hot and cold foods, ideal for on-the-go consumption.

– Baking containers:

Such as cake molds and pie pans, they can withstand the high temperatures of baking and effectively retain the moisture and flavor of food.