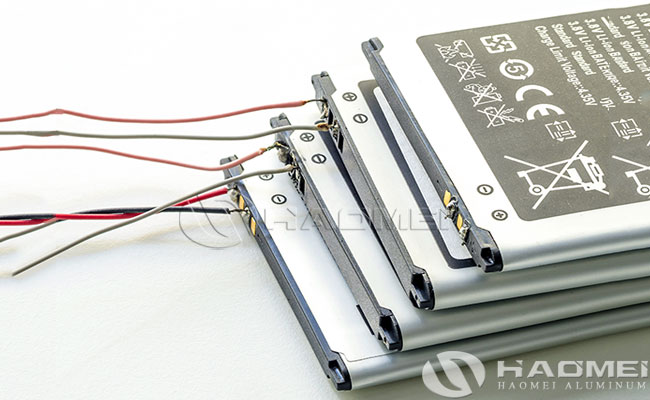

Aluminum foil for battery anode substrate is the positive current collector in lithium batteries and the carrier of lithium battery cathode slurry. It plays an important role in lithium batteries. Lithium batteries have high requirements for product safety, so it is also necessary to Strictly grasp the strength and technical level of suppliers. With more than 20 years of production and export experience as a guarantee, Haomei Aluminum offer high quality battery aluminum foil to make every lithium power plant feel at ease and comfortable to use.

Specification Description of aluminium foil for battery anode substrate:

Thickness: 0.008-0.02mm

Width: 400-1350mm

Common alloy state: 1070-H18, 1100-H18, 3003-H18

Application fields: mobile phone or electric vehicle battery

Important characteristics of aluminum foil for battery anode substrate:

- The surface of the battery aluminum foil should be uniform in color, clean, flat in shape, free of aluminum chips, aluminum powder, corrosion marks, obvious roll marks, crushed pits and other defects that affect use.

- The surface has no rolling defects such as mottled, herringbone, bright lines that affect the use and surface color difference that affects the use.

- The oil level on the surface of the battery aluminum foil in the H18 state should reach 31 dynes, and our company can provide battery foils up to 33 dynes at present, without oil spots and serious oily smell.

Advantages of aluminum foil for battery anode substrate:

- The main products of battery aluminum foil are 8079, 8021 aluminum alloy coils. The surfaceofaluminum foil produced by Haomei Aluminum is clean, flat and free of oil. At the same time, the battery aluminum foil has good pressure and puncture resistance.

- The strength of the aluminum foil for battery produced by Haomei Aluminum can reach 90-110Mpa, the extension is 13%-18%, the cup is 6.2-7.3mm, and the surface is free of oil, pinholes, bumps, scratches, and oxidation, foreign matter wrinkles, etc. In terms of equipment configuration, it is equipped with an online pinhole detector and ultrasonic welding to meet the slitting and processing of a series of high-end products such as batteryaluminum foil, and the material rack is 5-layer material rack. Effectively improve the surface cleanliness of aluminum foil.